Johnson/Evinrude Marine engines - A 1975 50 HP johnson idles rough at a low idle but smooths out at high RPM.

- Home

- Forum

- Outboard motors

- Johnson Evinrude Marine engines

- A 1975 50 HP johnson idles rough at a low idle but smooths out at high RPM

Forum -> outboard motors -> Johnson/Evinrude Marine engines

I have a 1975 50 HP johnson outboard. It idles rough at a low idle but smooths out at high RPM...

I have a 1975 50 HP johnson outboard. It idles rough at a low idle but smooths out at high RPM. Also the overheat buzzer goes off after about 5 monutes. I replaced the water pump with no help. Is there a thermostat installed on this motor? Do you have any iseas?

Thanks Austin.

Hi Austin,

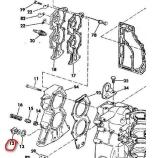

There s a thermostat on this engine and its located on the bottom of the cylinder head please see diagram, pn:5005440

Orc

So will I have to pull the cylinder head to get to it and replace the head gasket? What about the idling situatiuon?

The cylinder head itself doesnt need to come off but the water jacket will need to be removed (no: 18)

Sorry I thought I answered the idle problem doh,

Ok with the idle the would do a compression check the compressions on both cylinders should be over 100psi each and within 15psi of each other, if the engine has severely overheated then there is a chance that internal piston damage has occurred the compression check will determine this.

I did a cpmpression check and the results were 130 and 140 so I don't believe the cyliders or pistons have been damaged. I put new plugs in and I think my next step is going to be a carburetor kit. What do you think?

Hi Austin, compression is good, Yes I think you are right in aiming for the carbs being an issue, it is also worth checking the plug caps and ht leads as corrosion here can give a poor idle scenario but initially yes carbs is where I would goto, please read my guide below which is the order that I use to determine problems, it may be of some use now and in the future.

The Following information is the routine I use in discovering where a fault lies, it is quite generic and applies to most outboard motors, once you have read the information and found that a fault is still residing on your engine please let me know and we can move forward onto other possibilities you dont need to press accept until you are happy with the answer and you can keep the question open until you are happy.

First you need to diagnose what the fault could possibly be, First checks to always undertake

would be a spark test and compression test, this will rule out an spark problem and a serious

mechanical failure.

The spark test should always be done with safety in the forefront of your mind

the flywheel is spinning and can do a lot of damage,

remove the plugs from the cylinders get a good source for grounding them on the engine block and make sure that they stay grounded, if

the spark is not allowed to go to ground it can feed back through the ignition system and damage

the Ignition, crank the engine and ensure that all cylinders have a bright blue spark, this test

can also be done with an inductive timing light(with plugs left in) or a "glass" spark plug

which plugs between the HT lead and the plug, whilst doing the spark check with the plugs removed

you can put a compression tester onto each cylinder and check compression, compression should

always read over 100psi and within 15psi of each cylinder, if the readings fall outside of these

figures then the chances are you will need to have the engine overhauled as some internal wear/

damage has occurred, an engine with all 3 cylinders at 90psi can still idle ok but will not develop

the HP required to run efficiently, if the spark and compression tests come back good then you can

assume that the fuel system is where the problem lies, firstly check that you have good fuel and

not contaminated old fuel, modern fuels only have a shelf life of a couple of months before they

start deteriorating so if you are using last years fuel this can cause problems, if the fuel is good

then your next thing to check is that all fuel lines up to and including the engine are in good

condition with no cracks splits or poor connections, change the fuel filters as they can block and

restrict fuel flow, check your fuel pump diaphragms as any splits or holes will cause an engine to

run inefficiently, if you have a hole in a diaphragm the fuel will usually pass straight into

the crankcase and "over fuel" the engine this is because most fuel pumps are vacuum driven directly from

the crankcase pressure. If all these checks are sound then move onto the carb/s the carbs will need to

be removed, stripped and cleaned, I use a product by Quicksilver called Power tune to clean the carbs

this product dissolves salt residue and the "varnish" just spray it all over the carb components leave for

a few minutes and spray them clean, I dont recommend the use of high pressure air lines as this can

sometimes push a blockage further into a recess and cause more problems, if the blockage is very bad then

you could take the carbs to a specialist who has an Ultrasonic Cleaner In an ultrasonic cleaner, the object

to be cleaned is placed in a chamber containing a suitable ultrasound conducting fluid. The main mechanism

of cleaning action is by energy released from the creation and collapse of

microscopic cavitation bubbles, which break up and lift off dirt and contaminants from the surface to be

cleaned. The higher the frequency, the smaller the nodes between the cavitation points which allows for more

precise cleaning. The bubbles created can be as hot as 10,000 degrees and 50,000 lbs per square inch, but

are so small that cleaning and removal of dirt is the main result.

Whilst the carbs are off check the Reed valves on the inlet manifold for cracks breaks and even a reed missing completely the reed valves are to help control when the fuel is drawn into a cylinder if one has broken you will need to investigate to ensure that no internal damage has happened to the engine this will usually show up on the compression test with an abnormally low reading ie below 100psi.

When you reinstall the carb/s if you have 2 or more you will need to ensure that the carbs are synchronised this is vital to the idle of an engine basically when you put the carbs back on and adjust any idle you must ensure that all the carbs butterfly's are completely closed at idle, this ensures that a cylinder is not trying to run faster than the others or vice versa.

I have a 1988 Evanrude motor has a rough idle could you tell me what RPM it should run with muffs and water

Hose attached thank you